Virginia State EEOICPA Statistics

DOL Part B and Part E Statistics

NIOSH Dose Reconstruction Statistics

Virginia EEOICPA Facilities

Facility descriptions credit: DOE

Babcock and Wilcox

Company's main plant at Mount Athos and the

Lynchburg Research Center, also known as the

Lynchburg Technology Center in Lynchburg, VA,

performed work for a variety of Atomic Energy

Commission (AEC) and DOE projects.

Babcock

and Wilcox Company's Nuclear Facilities Plant in

Lynchburg, VA, participated in the AEC's Oxide

Pellet Fabrication Program, which was managed by

the New York Operations Office. Records indicate

that shipments of enriched uranium were made to

and from the Fernald facility during the years

1968-1972. The company also recovered highly

enriched uranium from weapons scrap received

from the DOE's Oak Ridge facility between 1985

and 1996. In 1997 the Babcock & Wilcox Company

facility in Lynchburg, VA became the BWX

Technologies facility. From 1998 to 2000, the

company fulfilled a contract for the recovery of

enriched uranium from scrap materials containing

beryllium. The Lynchburg plant also participated

in a DOE-sponsored program called Project

Sapphire, under which the plant had

responsibility from 1995 to 2001 for

downblending enriched uranium obtained from the

government of Kazakhstan.

During the period

of residual contamination, as designated by the

National Institute for Occupational Safety and

Health and as noted in the dates above,

employees of subsequent owners and operators of

this facility are also covered under the Energy

Employees Occupational Illness Compensation

Program Act.

The Thomas Jefferson National Accelerator Facility is a basic research laboratory built to probe the nucleus of the atom to learn more about the quark structure of matter.

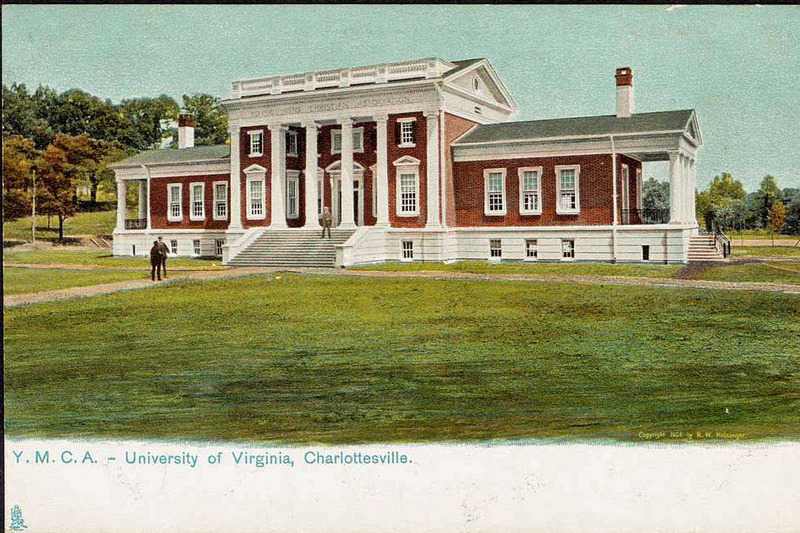

The University of

Virginia was involved with centrifuge technology

prior to the existence of the Manhattan Engineer

District (MED). Once established, the MED was

interested in this technology and records show

that the University of Virginia received UF6

from Harshaw Chemical Company in various

shipments as part of the MED’s efforts to

explore the use of this technology for the

production of UF6 in nuclear weapons. The MED

ultimately did not choose this method of uranium

production for the development of the bomb and

work on centrifuges temporarily ceased at the

University of Virginia by the end of 1944. The

centrifuge work was re-initiated in the mid-1950

but this latter work did not involve the

production of nuclear material for use in an

atomic weapon.

During the period of residual

contamination, as designated by the National

Institute for Occupational Safety and Health and

as noted in the dates above, employees of

subsequent owners and operators of this facility

are also covered under the Energy Employees

Occupational Illness Compensation Program Act.