EEOICPA Statistics for Claimants Living in Colorado

DOL Part B and Part E Statistics

NIOSH Dose Reconstruction Statistics

Colorado EEOICPA Facilities

Facility descriptions credit: DOE

Photo Credit: David on Pixabay

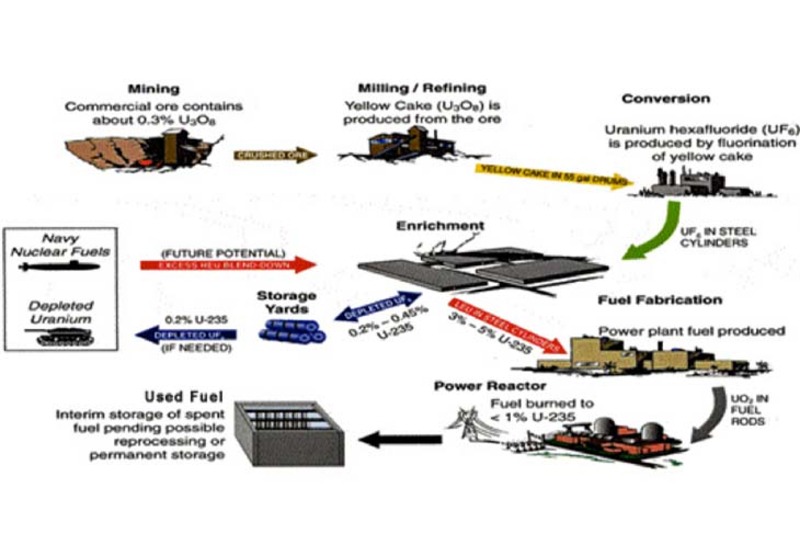

Canon City Uranium Mill Site is located in Fremont County, Colorado and is not currently covered as a DOE site under EEOICPA but is covered under RECA 5 (Radiation Exposure Compensation Act (RECA). Workers who have been awarded under RECA 5 at the Canon City Uranium Mill are eligible to file a Part E EEOICPA claim.

During its 19 years of operation, the mill produced 2.2 million tons of radioactive tailings. These years of operation are covered under the auspices of the Radiation Exposure Compensation Act and are not separately covered under EEOICPA. However, DOE environmental remediation contractors performed environmental remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) at this former uranium ore processing mill from at this former uranium mill from December 1988 through August 1994. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

Coors Porcelain

performed beryllium work for the Atomic Energy

Commission. An early AEC document makes

reference to Coors Porcelain’s involvement in

beryllium work during the period from 1947-1948.

Coors Porcelain had an earlier contract with the

Clinton Engineer Works but it is unclear whether

beryllium was involved.

From 1957 through

1964, the company worked as a subcontractor with

Lawrence Livermore National Laboratory on

Project Pluto, a project undertaken to determine

the feasibility of using heat from reactors as

the energy source for ramjet engines. Coors

developed fuel elements from beryllium ceramics

for the project, which began in 1957 and ended

in 1964.

Coors Porcelain performed other

beryllium work for DOE after the completion of

Project Pluto. A 1993 health study of Coors

workers indicated that the company produced

beryllia ceramics though 1975, presumably for

the AEC/DOE. In 1985, the vendor discovered

residual beryllium contamination in the building

where it had done beryllium work for the AEC,

and hired a private contractor to remediate and

demolish the building. The contractor completed

this remediation work by the end of 1985.

The Denver Uranium Mill is currently only a RECA 5 covered facility.

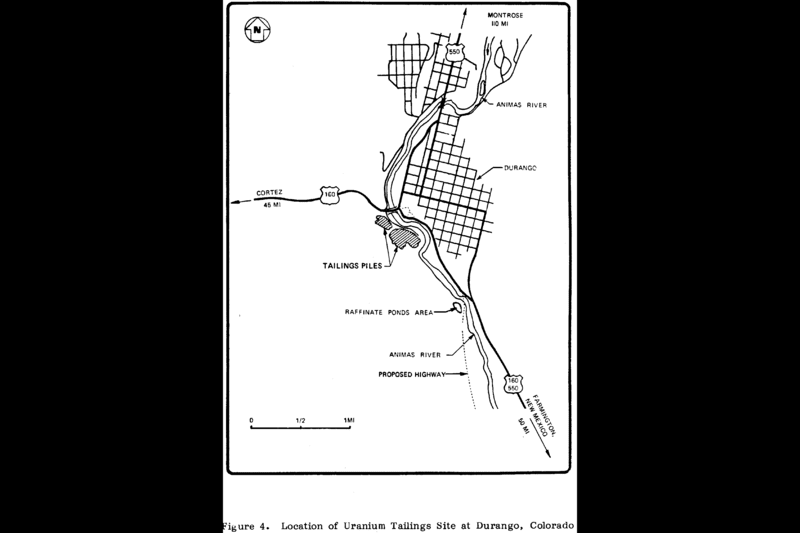

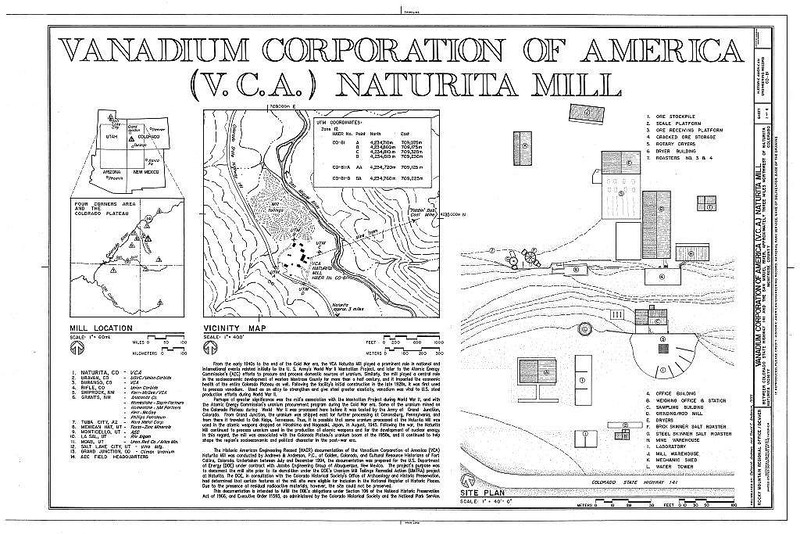

The AEC purchased

the 147-acre uranium mill site in Durango,

Colorado, in 1948 from the Vanadium Corporation

of America. The AEC leased the facility back to

Vanadium that same year, with an option to

purchase the facility in 1953. Between 1948 and

1953, Vanadium operated the mill on behalf of

the AEC. The company exercised its purchase

option in 1953, and thereafter, the mill was

operated as a privately owned facility. The

company shut down and dismantled the mill in

March 1963.

Additionally, from October 1986

through May 1991, DOE environmental remediation

contractors performed environmental remediation,

under the Uranium Mill Tailings Radiation

Control Act (Public Law 95-604) at this mill.

DOE and DOE contractor employees who performed

this remediation are covered under EEOICPA.

The Gateway Uranium Mill is currently only a RECA 5 covered facility.

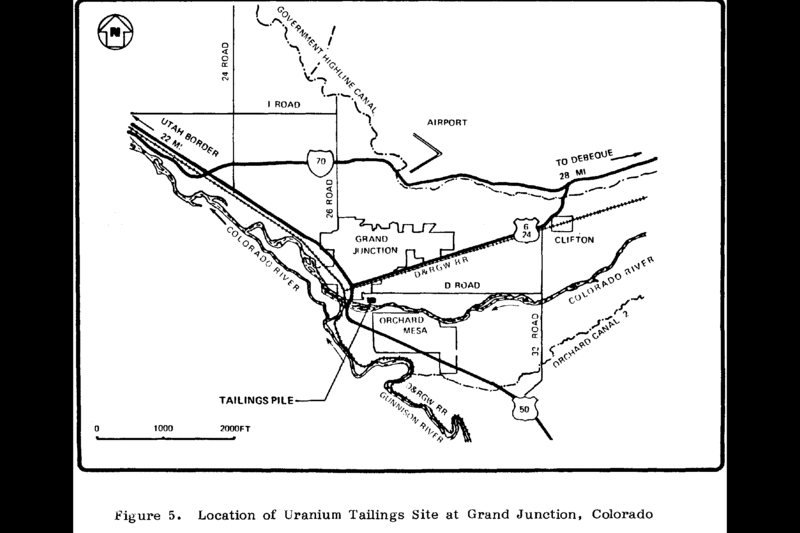

The Manhattan

Engineer District (MED) constructed a uranium

refinery (mill) to produce uranium concentrate

from “green sludge here in 1943 which it

operated through 1946.” This location also

served as the headquarters for the U.S. Atomic

Energy Commission’s (AEC) uranium-procurement

program from 1947 through 1970 and was known as

the Grand Junction Office. One of the principal

functions of the site was the receipt, sampling,

and analysis of uranium and vanadium

concentrates from the numerous ore-processing

operations in the western United States. In

1951, the AEC constructed a concentrate sampling

plant, assay laboratory, and two ore-testing

pilot plant mills at this facility. Furthermore,

the AEC established a sampling and assaying

station for the receipt of uranium ores at Grand

Junction. Concentrates produced by mills were

delivered in steel drums to Grand Junction,

where they were received, weighed, sampled, and

assayed as the basis for payment to the mills

under the terms of their respective contracts.

On September 30, 2001, the Department of Energy

transferred ownership of the Grand Junction

property to the Riverview Technology

Corporation. The DOE, however, continues to

lease portions of the site and provides some

on-going remediation services as well as

Long-Term Surveillance and Maintenance at the

site.

The Manhattan

Engineer District (MED) constructed a uranium

refinery (mill) to produce uranium concentrate

from “green sludge here in 1943 which it

operated through 1946.” This location also

served as the headquarters for the U.S. Atomic

Energy Commission’s (AEC) uranium-procurement

program from 1947 through 1970 and was known as

the Grand Junction Office. One of the principal

functions of the site was the receipt, sampling,

and analysis of uranium and vanadium

concentrates from the numerous ore-processing

operations in the western United States. In

1951, the AEC constructed a concentrate sampling

plant, assay laboratory, and two ore-testing

pilot plant mills at this facility. Furthermore,

the AEC established a sampling and assaying

station for the receipt of uranium ores at Grand

Junction. Concentrates produced by mills were

delivered in steel drums to Grand Junction,

where they were received, weighed, sampled, and

assayed as the basis for payment to the mills

under the terms of their respective contracts.

On September 30, 2001, the Department of Energy

transferred ownership of the Grand Junction

property to the Riverview Technology

Corporation. The DOE, however, continues to

lease portions of the site and provides some

on-going remediation services as well as

Long-Term Surveillance and Maintenance at the

site.

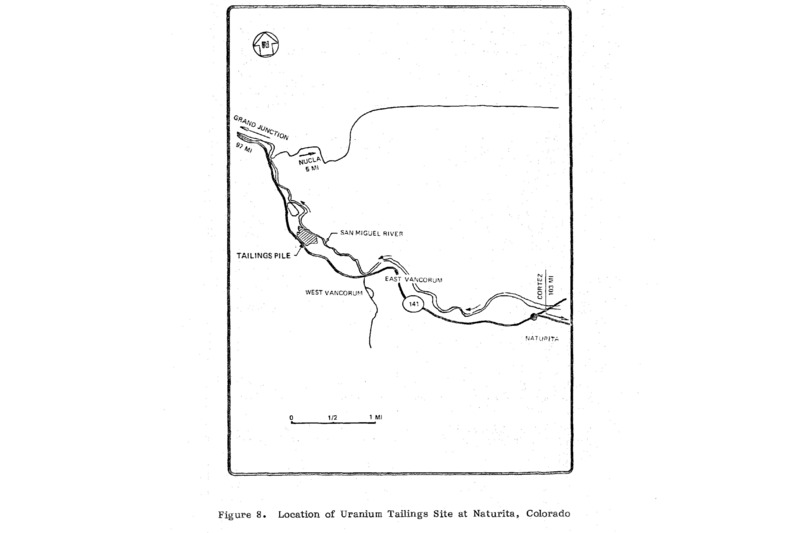

The Manhattan Engineer District (MED) obtained uranium from residues left over from the production of vanadium. The resulting product made at these plants was called "green sludge." It was further processed at Grand Junction. Two plants in Uravan, Colorado, provided the MED with uranium extracted from green sludge. The green sludge plant in Uravan owned by Union Carbide and operated by its subsidiary, the U.S. Vanadium Company, is not covered under EEOICPA. This listing applies only to the MED-owned plant, which was located on the north side of the San Miguel River. The U.S. Vanadium Company operated the MED-owned plant under a fixed fee contract during World War II. The plant was shut down in 1945.

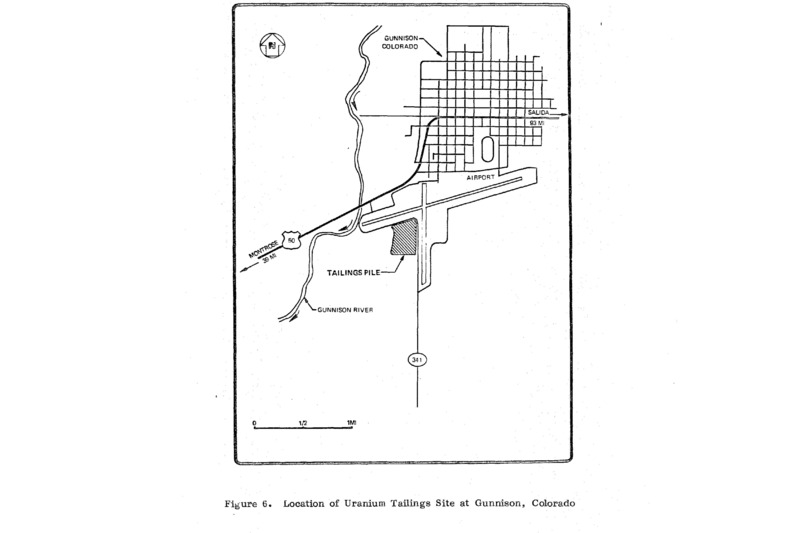

This mill processed approximately 540,000 tons of uranium ore between 1958 and 1962. This ore processing is covered under the auspices of the Radiation Exposure Compensation Act and is not separately covered under EEOICPA. However, DOE environmental remediation contractors performed environmental remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) at this former uranium ore processing mill from September 1991 though December 1995. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

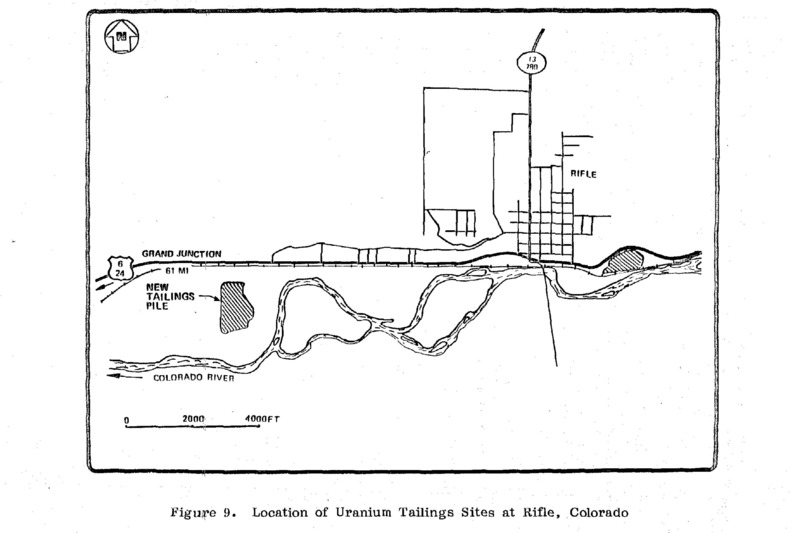

During its 7 years of operations, this uranium mill processed about 2.6 million tons of ore. This ore processing is covered under the auspices of the Radiation Exposure Compensation Act and is not separately covered under EEOICPA. However, DOE environmental remediation contractors performed environmental remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) at this former uranium mill from May 1995 through September 1998. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

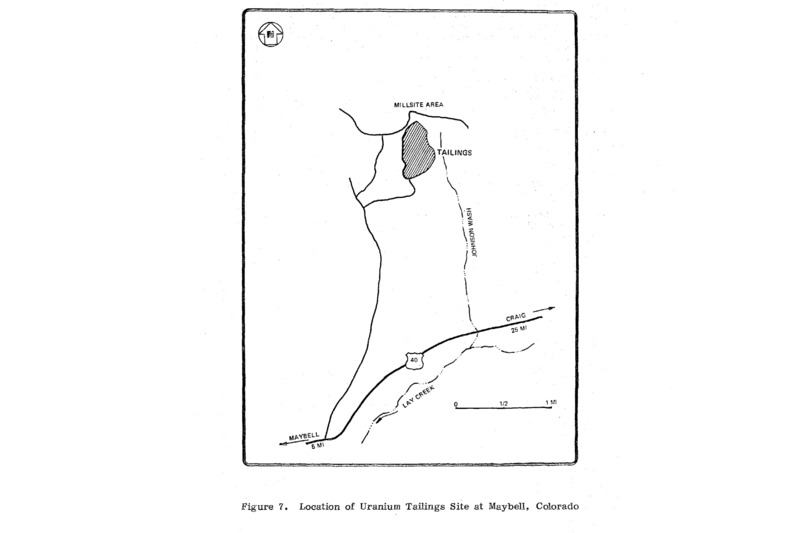

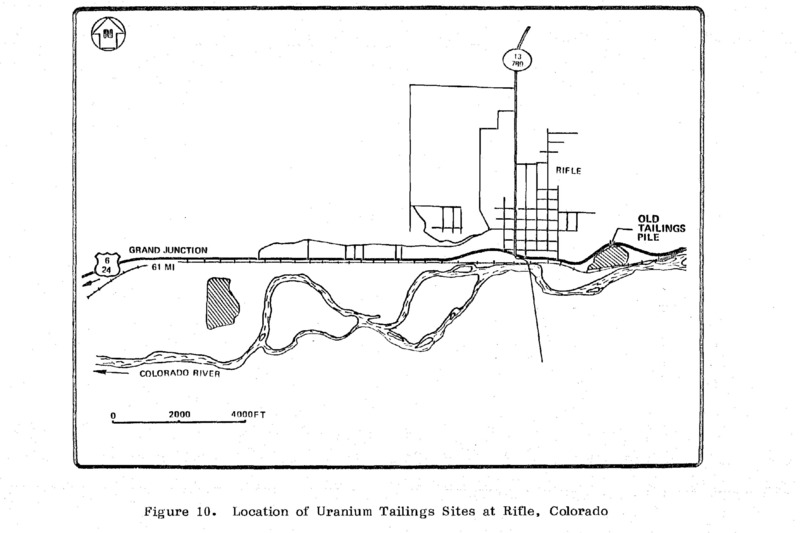

This former uranium and vanadium ore processing facility processed about 704,000 tons of ore. This ore processing is covered under the auspices of the Radiation Exposure Compensation Act and is not separately covered under EEOICPA. However, DOE environmental remediation contractors performed environmental remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) at this former processing site from May through November of 1994 and again from June of 1996 through September 1998. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

The Rio Blanco site was the location of one of the nuclear tests conducted as part of the AEC's Plowshare program that was initiated in 1957 to develop peaceful (industrial and scientific) applications for nuclear explosives. The operational period began May 2, 1973. On May 17, 1973, three 33 kiloton yield nuclear devices were detonated in a deep well in a test designed to increase natural gas production from low-permeability sandstone. These explosions, known as the Rio Blanco shot, marked the last nuclear test explosions of the Plowshare program. The operation ended in June 1976. The Rio Blanco site was plugged and abandoned in 1976 and returned to the owner in March 1978.

The Project Rulison site was the location of one of the nuclear test explosions conducted as part of the AEC's Plowshare program, which was initiated in 1957 to develop peaceful (industrial and scientific) applications for nuclear explosives. Drilling began in May 1968. On September 10, 1969, a forty kiloton yield nuclear device was detonated deep underground in a sandstone formation. The test was designed to increase natural gas production from low-permeability sandstone. Drillback operations began in April 1970 and the rubble chimney was reached on July 28, 1970. Preparation for production flaring continued through August 1970 and included several short flaring tests during August. The production flaring operation began on October 4, 1970. It included for different flaring periods and ended on April 23, 1971. The Rulison site was placed on standby status in May 1971 until June 1972 when cleanup operations were initiated. The site was returned to its owner in March 1978.

From 1958 to 1973, the mill produced uranium and vanadium concentrates and from 1973 to 1984 part of the mill was used to produce vanadium concentrate. These milling operations are covered under the auspices of the Radiation Exposure Compensation Act and are not separately covered under EEOICPA. However, DOE environmental remediation contractors performed remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) of hazardous materials such as asbestos, industrial chemicals, and other materials at the site from September 1988 through September 1989 and then performed remediation of all contaminated mill tailings at the site from April 1992 through October 1996. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

This mill was operated for two periods, namely 1924 through 1932 and again from 1942 to 1958. During these both these time periods it processed vanadium ore. Uranium ore was processed only in the latter period. These milling operations are covered under the auspices of the Radiation Exposure Compensation Act and are not separately covered under EEOICPA. However, DOE environmental remediation contractors performed remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) of hazardous materials such as asbestos, industrial chemicals, and other materials at the site from September 1988 through September 1989 and then performed remediation of all contaminated mill tailings at the site from April 1992 through October 1996. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

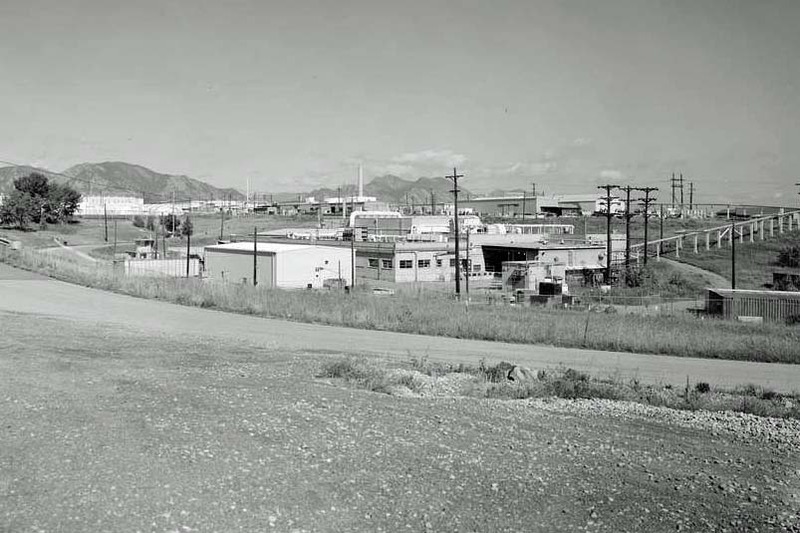

Rocky Flats

was built in 1951 as a plutonium and uranium

component manufacturing center. From 1952 to

1989, the site's primary mission was to

fabricate the "pit" that contains the heavy

metals and serves as the trigger device for

nuclear warheads. Rocky Flats was also

responsible for recycling plutonium from scrap

and plutonium retrieved from retired nuclear

warheads. The final products of this recycling

included components and assemblies manufactured

from uranium, plutonium, beryllium, stainless

steel, and other metals. Production activities

included metalworking, component fabrication and

assembly, chemical recovery and purification of

plutonium, and associated quality control

functions. Research and development in the

fields of chemistry, physics, metallurgy,

materials technology, nuclear safety, and

mechanical engineering were also conducted at

the site.

In 1989, many of the site's nuclear

component production functions were suspended

after a safety review temporarily shut down

plutonium operations. Following an extensive

review, which included considerable independent

oversight, a few buildings were authorized by

the Secretary of Energy to resume limited

plutonium operations: to stabilize plutonium

oxide and repackage plutonium for safe storage.

In 1989, as a result of the environmental

contamination caused by production activities at

the site, Rocky Flats was placed on the

Superfund National Priorities List. In January

1992, nuclear component production was

terminated and the site's primary mission

changed from nuclear weapons production to

environmental cleanup and restoration.

Throughout the course of its operations, the

potential for beryllium exposure existed at this

site, due to beryllium use, residual

contamination, and decontamination activities.

Shattuck Chemical

prepared uranium compounds and uranium oxide in

the late 1950s. (This was probably done under a

Source Materials License issued by the Atomic

Energy Commission.) Shattuck also processed

refined uranium and produced natural uranium

oxides on a commercial basis for the private

market, and in 1963, supplied a small quantity

of uranium to the Rocky Flats plant.

During

the period of residual contamination, as

designated by the National Institute for

Occupational Safety and Health and as noted in

the dates above, employees of subsequent owners

and operators of this facility are also covered

under the Energy Employees Occupational Illness

Compensation Program Act.

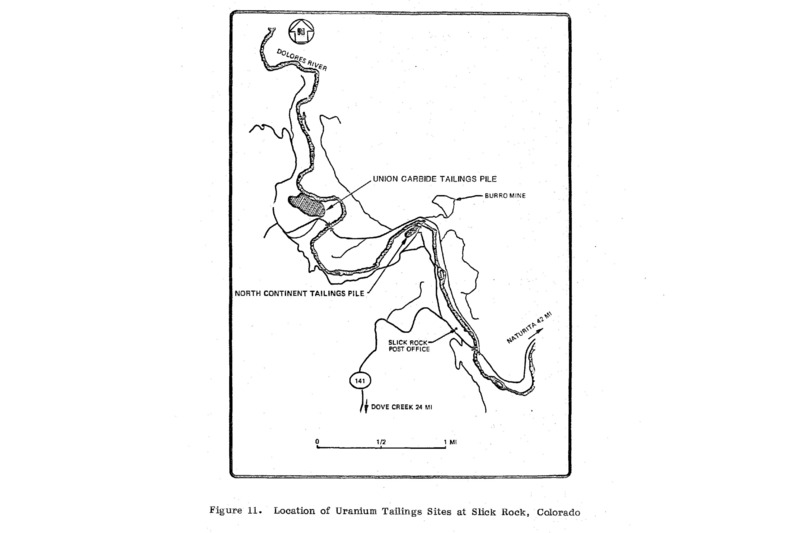

This mill extracted

radium salts and vanadium from locally mined

ores between 1942 and 1943. These milling

operations are covered under the auspices of the

Radiation Exposure Compensation Act and are not

separately covered under EEOICPA. However, DOE

environmental remediation contractors performed

remediation under the Uranium Mill Tailings

Radiation Control Act (Public Law 95-604) at

Uranium Mill No. 1 in Slick Rock from 1995-1996.

DOE and DOE contractor employees who performed

this remediation are covered under EEOICPA.

Vanadium and uranium was processed at this mill from 1957 through 1961. These milling operations are covered under the auspices of the Radiation Exposure Compensation Act and are not separately covered under EEOICPA. However, DOE environmental remediation contractors performed remediation under the Uranium Mill Tailings Radiation Control Act (Public Law 95-604) at Uranium Mill No. 2 in Slick rock from 1995-1996. DOE and DOE contractor employees who performed this remediation are covered under EEOICPA.

The University of

Denver Research Institute is listed as a

processor of radioactive materials for National

Lead of Ohio (Fernald). It appears that the

University of Denver handled test quantities of

radioactive metal in February 1965.

In 1963,

a University of Denver Research Institute

researcher (F. Perkins) held an AEC contract for

work on intermediate-temperature oxidation of

beryllides.

.jpg)